-

Alüminyum Şerit Rulo

-

Renk Kaplı Alüminyum Bobin

-

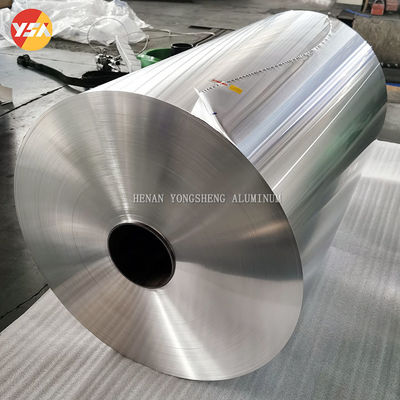

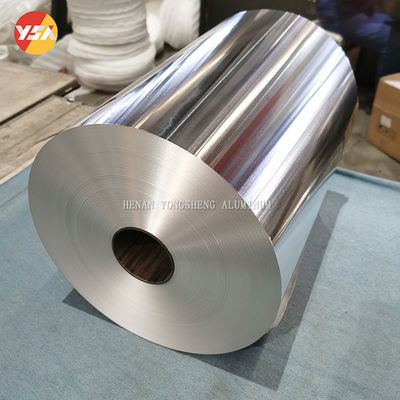

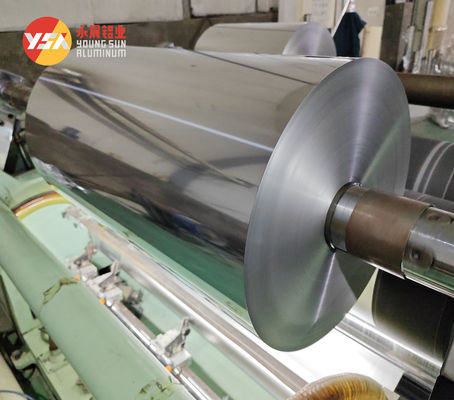

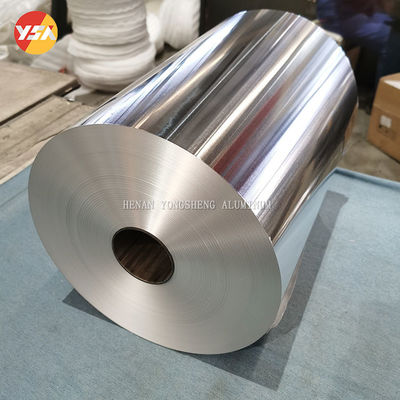

Alüminyum Folyo Rulo

-

Alüminyum tabak

-

Alüminyum Çember Disk

-

Alüminyum folyo laminatlı poliester filmi

-

Alüminyum Damalı Levha

-

Alüminyum Elmas Levha Levha

-

Kabartmalı Alüminyum Levha

-

Eloksallı alüminyum levha

-

Ayna Alüminyum Levha

-

Alüminyum folyo kap

-

Alüminyum Folyo Öğle Yemeği Kutusu

-

Tek kullanımlık barbekü ızgara

-

kırlangıçYongsheng Aluminium ile ilk işbirliği yaptığımızda, bunu çok kolay bulduk, çünkü malların teslim süresi çok hızlıydı ve işletme müdürü de çok profesyoneldi.

kırlangıçYongsheng Aluminium ile ilk işbirliği yaptığımızda, bunu çok kolay bulduk, çünkü malların teslim süresi çok hızlıydı ve işletme müdürü de çok profesyoneldi. -

Alice SuŞirketimiz ve Yongsheng Alüminyum yaklaşık üç yıldır işbirliği yapıyor.

Alice SuŞirketimiz ve Yongsheng Alüminyum yaklaşık üç yıldır işbirliği yapıyor. -

ZoeyYongsheng Alüminyum'dan alüminyum daire satın alıp Gana'ya gönderiyoruz.

ZoeyYongsheng Alüminyum'dan alüminyum daire satın alıp Gana'ya gönderiyoruz. -

Amin MazlumYongsheng Alüminyum'dan toplamda yaklaşık 500 ton kabartmalı renkli alüminyum rulo satın aldık.

Amin MazlumYongsheng Alüminyum'dan toplamda yaklaşık 500 ton kabartmalı renkli alüminyum rulo satın aldık.

0.012-0.1mm 3003 H13 Bal sapı folyoları için alüminyum folyo

| Alaşım | 3003, vb. | Temperatör | H18, H19, vb. |

|---|---|---|---|

| Kalınlığı | 0,012-0,1 mm | Genişliği | 180-1350 mm |

| Uzunluk | Müşteri gereksinimleri | Performans | Gerilme mukavemeti> 240 mpa, kırıldıktan sonra uzama>% 1 |

| Liman | Şanghay, Tianjin, Qingdao | Örnek | Özgür |

| Vurgulamak | ultra ince alüminyum folyo rulo,3003 H13 bal sapı folyoları,0.012mm alüminyum folyo tabakası |

||

| Özellik | Değer |

|---|---|

| Alaşım | 3003, vb. |

| Temperatör | H18, H19, vb. |

| Kalınlığı | 0.012-0.1mm |

| Genişliği | 180-1350 mm |

| Uzunluk | Müşteri Gereksinimleri |

| Performans | Çekim sıklığı> 240 MPa, kırılmadan sonra uzatma> 1% |

| Liman | Şangay, Tianjin, Qingdao. |

| Örnek | Özgür |

0.012-0.1mm 3003 H13 Bal sapı folyoları için alüminyum folyo

- Kompozisyon temeli: Alüminyum-manganez alaşımı (Mn yaklaşık 1.0-1.5%)

- Güçlendirme mekanizması: Saf soğuk çalışma sertleştirme (sıfır işlemsiz güçlendirme)

- Yüksek dayanıklılık: Soğuk işleme ile elde edilen yüksek dayanıklılık seviyesi

- Yüksek sertlik: Yüksek yüzey sertliği ve nispeten iyi aşınma direnci

- Düşük esneklik: Düşük plastiklik ve sınırlı şekillendirilebilirlik. Derin çizim gibi şiddetli şekillendirme işlemleri için uygun değildir

- İyi korozyon direnciyi koruyun: Atmosfer ortamında ve birçok kimyasal ortamda mükemmel korozyon direnci

- İyi kaynaklılık: Ancak kaynakın ısıdan etkilenen bölgesi yumuşayacaktır (güç azalır)

- İyi işlenebilirlik: İşlenebilir, ancak yumuşak durumdan daha fazla alet gerektirir

Alüminyum folyoyu bal demiri çekirdeğine dönüştürmek, hassas ve yüksek otomatik bir işlemdir.Çekirdek, özel bir şekillendirme ve bağlanma süreci ile sürekli altıgen bir bal kovanı hücre yapısı oluşturmaktır..

Alüminyum folyo bobinlerini belirli sınıf 3003 ve kalınlığı ile seçin.Alüminyum folyo yüzeyi, daha sonraki yapıştırıcıların yapışkanlığını artırmak için yağsızlaştırılmalı ve kimyasal olarak tedavi edilmelidir (örneğin kromlama veya kromsuz işlem).

Alüminyum folyonun belirli yerlerine paralel çizgiler halinde yüksek dayanıklı yapıştırıcı uygulayın. Yapıştırıcı çizgilerin genişliği ve aralıkları nihai bal sapı hücrelerinin boyutunu ve şeklini belirler.Yapıştırma yöntemi: Yapıştırıcı hattının tekdüze, sürekli ve kesin bir şekilde konumlandırılmasını sağlamak için hassas rulo kaplama veya püskürtme.

Yapıştırılmış alüminyum folyo, bir dizi hassas dalgalanma rulolarından geçecek.Gömlek çizgilerinin aralıkları ile dalgalanmanın zirve mesafesi ve yüksekliği sıkı bir şekilde eşleşmelidir.

Preslenmiş dalgalanmış alüminyum folyoların birden fazla katmanını (genellikle düzinelerce ila yüzlerce katman) kesin bir şekilde hizalayın ve yığın.Her bir dalgalanmış alüminyum folyo tabakasının zirveleri, bitişik tabakadaki yapıştırıcı şeritlerin konumuyla tam olarak hizalandırılmalıdır..

Sıcak baskı veya sürekli sıcak baskı kemeri, laminat üzerine basınç ve ısı uyguluyor. Yapışkan erir, akıp kalkar ve bitişik dalgalanmış alüminyum folyolarının temas noktalarını sıkıca bağlar.Sertleştirildikten sonra, yapıştırıcı kaplamada bitişik alüminyum folyo katmanları arasında bağlanma noktaları oluşur ve kaplamamış dalgalanmış parçalar doğal olarak açılır ve bal kurusu hücrelerinin prototipini oluşturur.

Laminasyon ve sertleştirme sonrası, orijinal olarak ayrılmış çok katmanlı dalgalanmış alüminyum folyo, içi düzenli bir gözenek yapısı olan bütünleşik bir alüminyum bloğu haline gelir."Bal tarı yığını" ya da "bal tarı çekirdeği boş" olarak adlandırılır.Bu anda, bal sapı hücreleri alüminyum folyo düzlemine dik yönde bağlıdır, ancak alüminyum folyo düzleminin yanındaki hücreler henüz tamamen açılmamıştır.

Sertleştirme makinesine sertleştirilmiş bal sapı yığınının iki ucunu sabitleyin. Dalgalanma yönüne dik bir gerilim uygulayın.dalgalanmış alüminyum folyo katmanları arasındaki bağlanma noktaları sabit nokta olarak hizmet ederDalgalanmaların çukurları parçalanır ve orijinalde yığılmış hücresel yapılar akordeon gibi eşit şekilde yayılır.düzenli bir üç boyutlu bal kurusu yapısı, sürekli, altıgen hücre hücreleri oluşur. hücre hücrelerinin yırtılmadan veya deformasyon olmadan eşit şekilde açılmasını sağlamak için gerilme hızı ve gücü kesin bir şekilde kontrol edilmelidir.

| Alaşım | 3003, vb. |

| Temperatör | H18, H19, vb. |

| Kalınlığı | 0.012-0.1mm |

| Genişliği | 180-1350 mm (tolerans:± 1.0mm) |

| Uzunluk | Gereksinimlerinize göre. |

| Özellik | Çevre dostu |

| Paket | Standart Denizcilik Paketi |

| Türü | Yüksek saflıklı alüminyum folyo bobini |

| Renk | Gümüş |

| Şekli | Alu sarmal |

| Sertlik | O/HO |

| İletkenlik (% IACS) | ≥61.5 |

| Uzunluk (%) | > 23 |

| Uygulama | Endüstri, Dekorasyon, İnşaat, Paketleme, Presleme vb. |

| Yüzey işlemi | Dökme, kaplama, toz kaplama, anodizasyon, cilalı ayna, embossed, vb. |