-

Alüminyum Şerit Rulo

-

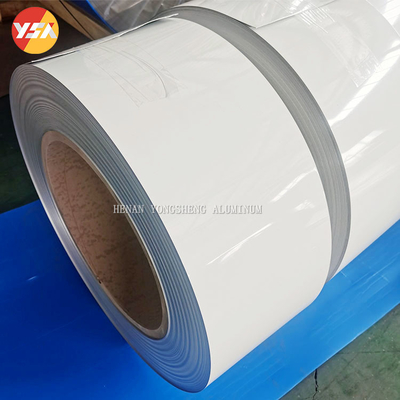

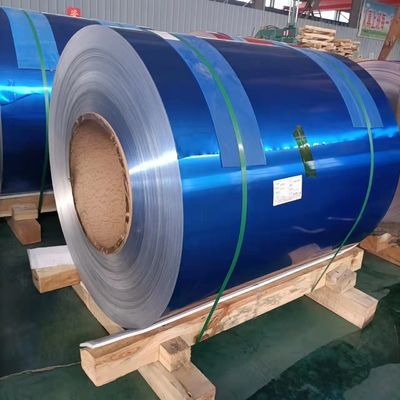

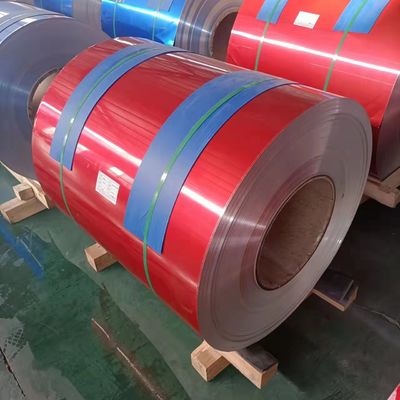

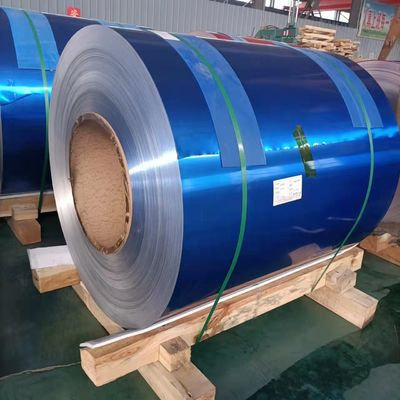

Renk Kaplı Alüminyum Bobin

-

Alüminyum Folyo Rulo

-

Alüminyum tabak

-

Alüminyum Çember Disk

-

Alüminyum folyo laminatlı poliester filmi

-

Alüminyum Damalı Levha

-

Alüminyum Elmas Levha Levha

-

Kabartmalı Alüminyum Levha

-

Eloksallı alüminyum levha

-

Ayna Alüminyum Levha

-

Alüminyum folyo kap

-

Alüminyum Folyo Öğle Yemeği Kutusu

-

Tek kullanımlık barbekü ızgara

-

kırlangıçYongsheng Aluminium ile ilk işbirliği yaptığımızda, bunu çok kolay bulduk, çünkü malların teslim süresi çok hızlıydı ve işletme müdürü de çok profesyoneldi.

kırlangıçYongsheng Aluminium ile ilk işbirliği yaptığımızda, bunu çok kolay bulduk, çünkü malların teslim süresi çok hızlıydı ve işletme müdürü de çok profesyoneldi. -

Alice SuŞirketimiz ve Yongsheng Alüminyum yaklaşık üç yıldır işbirliği yapıyor.

Alice SuŞirketimiz ve Yongsheng Alüminyum yaklaşık üç yıldır işbirliği yapıyor. -

ZoeyYongsheng Alüminyum'dan alüminyum daire satın alıp Gana'ya gönderiyoruz.

ZoeyYongsheng Alüminyum'dan alüminyum daire satın alıp Gana'ya gönderiyoruz. -

Amin MazlumYongsheng Alüminyum'dan toplamda yaklaşık 500 ton kabartmalı renkli alüminyum rulo satın aldık.

Amin MazlumYongsheng Alüminyum'dan toplamda yaklaşık 500 ton kabartmalı renkli alüminyum rulo satın aldık.

0.4/0.5mm 1060 3003 5052 Renkli Alüminyum Yaprak Rulo Al Bobine Kaplı

Ücretsiz numune ve kuponlar için bana ulaşın.

Naber:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Herhangi bir endişeniz varsa, 24 saat çevrimiçi yardım sağlıyoruz.

x| Alaşım/Sınıf | 1100 1050 1060 2024 5052 6061 | Temperatör | O-H112 |

|---|---|---|---|

| Kalınlığı | 0,2-300 mm | Genişliği | 10-3500mm, vb. |

| Kaplama | PE veya PVDF | Adedi | 3 ton |

| Liman | Şanghay, Tianjin, Qingdao | Menşe yeri | Henan Eyaleti, Çin |

| Vurgulamak | 0.4 mm renkli kaplı alüminyum bobini,5052 alüminyum kağıt rulo,1060 kaplamalı alüminyum bobin |

||

| Özellik | Değer |

|---|---|

| Alaşım/Kalite | 1100 1050 1060 2024 5052 6061 |

| Tav | O-H112 |

| Kalınlık | 0.2-300mm |

| Genişlik | 10-3500mm, vb. |

| Kaplama | PE veya PVDF |

| Minimum Sipariş Miktarı (MOQ) | 3 Ton |

| Liman | Şanghay, Tianjin, QingDao |

| Menşe Yeri | Henan Eyaleti, Çin |

Renkli kaplamalı alüminyum bobin, bir alüminyum bobinin yüzeyine çoklu organik kaplama katmanları uygulanarak oluşturulan bir kompozit malzemedir. Bu kaplamalar, renk kaplama ve ardından katmanları kürlemek için pişirme işlemiyle uygulanır.

Alüminyum alaşımlı bobinin yüzeyi renklidir, bu da onun kararlı performansına ve korozyona karşı direncine katkıda bulunur. Tipik olarak, rengini en az sekiz yıl boyunca koruyabilir. Bu malzeme, düşük yoğunluğu, yüksek sertliği ve hafif yapısıyla karakterizedir.

Renkli kaplamalı alüminyum bobin, hem alüminyum bobinin hem de organik malzemelerin faydalarını birleştirir. Alüminyum bobin ile ilişkili yüksek mekanik mukavemeti, iyi tokluğu ve kolay işleme ve şekillendirme özelliklerini korur. Ek olarak, organik polimer kaplamaların mükemmel renklendirme, dekoratif çekicilik ve korozyon direncini içerir. Bu malzeme, delme, bükme, derin çekme ve kaynak gibi işlemlere kolayca tabi tutulabilir. Ondan yapılan ürünler pratiktir, işlenmesi kolaydır ve dayanıklıdır.

Epoksi Reçine Astar:

- Çeşitli yüzeylere mükemmel yapışma sağlar

- Zorlu ortamlarda iyi kimyasal direnç gösterir

- Mükemmel korozyon direnci sunar

- Çok çeşitli üst katlarla uyumludur

- Yüksek aşınma direnci sergiler

- Bobin kaplama işlemleri sırasında mükemmel reolojik özellikler sergiler

Polyester Reçine Üst Kat:

- İyi film özellikleri, esneklik, sertlik ve işlenebilirlik özelliklerine sahiptir

- Bobin kaplama sırasında iyi tesviye sağlar

- Güçlü yapışma ve kimyasal direnç sergiler

- İyi hava koşullarına dayanıklılık sağlar

Epoksi Reçine Arka Kat:

- İyi film özellikleri, sertlik, çizilme direnci ve işlenebilirlik sağlar

- Bobin kaplama sırasında iyi tesviye sağlar

- Çok çeşitli yüzeylere mükemmel yapışma sağlar

| Özellik | Detaylar |

|---|---|

| Ürün Adı | Alüminyum Oluk Bobini |

| Alaşım | 1100 3003 1050 3105 5005, vb. |

| Kalınlık | 0.022mm - 3.0 mm |

| Genişlik | Standart genişlik: 1240mm; 1200mm Tüm genişlik: 30mm - 1600mm |

| Çap | Dış çap: 1200mm İç çap: 405mm, 505mm |

| Ağırlık | 2.5T/bobin, 3.0T/bobin |

| Kaplama | PE, PVDF |

| Yüzey | Kabartmalı, fabrikasyon yüzey, kaplamalı; alüminyum oluk bobini |

| Renk | Tüm RAL renklerine göre |

| Parlaklık | 10-90% (EN ISO-2813:1994) |

| Kaplama Kalınlığı | PE: 18 mikrondan fazla PVDF: 25 mikrondan fazla |

| Kaplama Sertliği (kurşun kalem direnci) | 2 saatten fazla |

| Kaplama yapışması | 5J (EN ISO-2409:1994) |

| Darbe Direnci | Soyulma veya çatlama yok (50 kg/cm, ASTMD-2794:1993) |

| MEK direnci | 100'den fazla |